Tools of the Trade

Pretty much the essence of this page is to show some of the tools and jigs ext. we’ve made on our journey of custom knife making. For anyone looking to take this path in life, the cost of equipment can be a bit overwhelming, combine that with the vast variety of plant and equipment you could buy if money’s not an issue, it’s hard to know where to start. Luckly though you don’t really need a lot of gear to start in the craft and in my humble opinion, learning the skills is far more important than having the best of gear.

And if you decide to look further into this page bear in mind that it’s all just my humble opinion about the stuff we use and things we’ve done. If any links are shown they’re not affiliate links, just ideas of places that made our lives easer, and may save you the hours of searching the internet as we did.

2 x 72 Belt Grinders

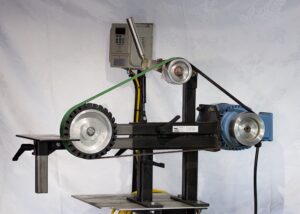

“Wyatt Louis Jane Belt Grinder MKI”

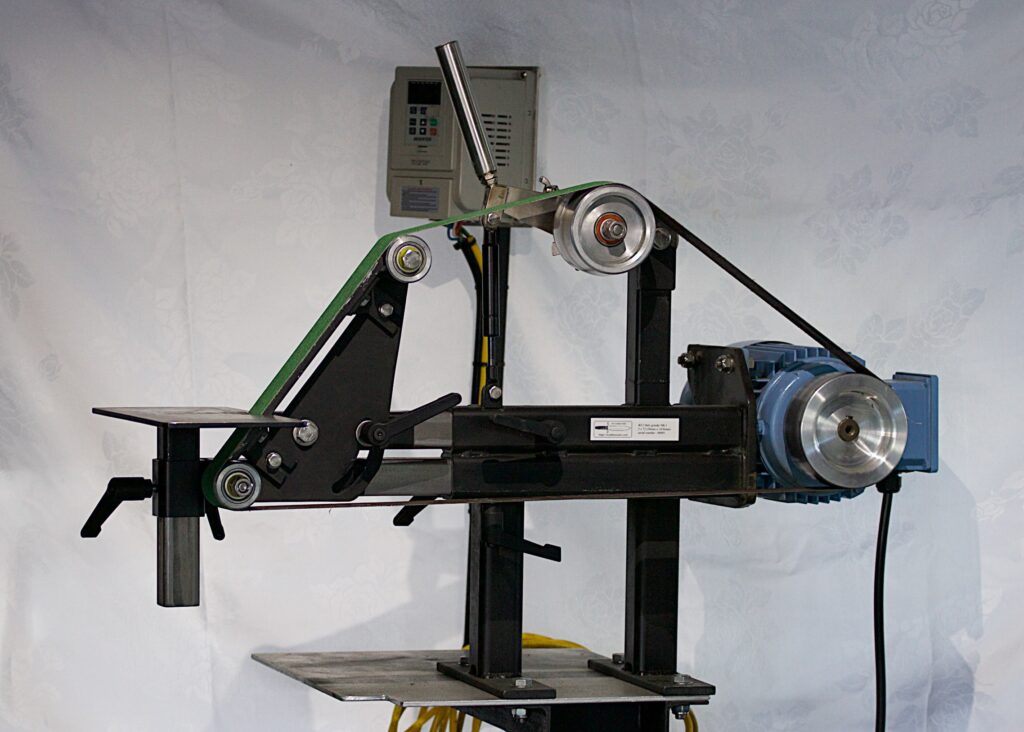

The Wyatt Louis Jane MKI 2 x 72 Belt Grinder, is something we’ve put together after countless hours of grinding knives, on many a belt grinder, weeks and weeks of research, and the need for a robust reliable 2 x 72 belt grinder. And here we have it, what’s show in the photos is the first one off the block, the prototype as it were. We’ve ironed out a few wee issues, made some slight improvements and it’s in service and running well, to the point where now we offer it by request, made to order, to anyone who may wish to add a quality 2 x 72 belt grinder to their array of workshop tools.

To the left is the prototype, the first one off the block, not the first grinder we ever made, but the first we’ve made to our own design from the ground up as it were.

This one’s fitted with a 3hp three phase motor run through a VFD making it usable in any single phase power outlet. Normally we’d run a 2hp motor but at the time 3hp is all we could get. If you decided you wanted to make one of these your own we’d size the motor and VFD to suit your needs and more importantly your budget.

It’s runs in forward or reverse and the VFD has an overload should anything go wrong, due to improper use, as has happened.

The tracking mechanism is duel action making tracking the belts a little bit easier than on some other models.

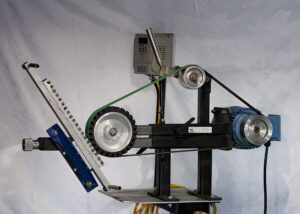

It’s a titling grinder working vertically or horizontally and has a variety of accessories that can be added such as small wheels, large contact wheels, different work tables, and a surface grinding type attachment.

What we have above is a couple or three of the attachments we’ve added to our 2 x 72 grinder. On the left is the small wheel attachment showing a 20mm diameter wheel in the horizontal position. Naturally it can be used in the vertical position as well, but this is normally how we use it. 20mm diameter is generally our go to wheel but sizes range from 12.5mm to 38mm custom made to suit what you need.

The middle photo shows the 8″ drive wheel which we generally use in conjunction with our surface grinding type attachment as show on the right. Note the chuck is held up for the purpose of the photo. Larger drive wheels could be fitted, or smaller I guess, as long as their 2″ wide. However having said that we could modify the tooling arm to take wider wheels if the need arose.

And speaking of adjustment, we’ve made a few modifications to the tracking mechanism. On the earlier models the tracking type hinge only rotated on one axis, meaning it had to be fitted exactly 90 degrees to the machine. So this being the case to allow ease of manufacture we decided to make it duel action, just to give more adjustment and to account for any weld distortion and the like.

Originally there was just a nut welded to the hinge on the top adjustment and then the idea of using a rod end came to me when welding a roll cage into a race car. Rod ends seemed to be everywhere under the hood of that machine.

Anyway much to my surprise, when using this system, the top adjustment is all that’s really needed to track the belt. The bottom adjustment is generally locked level and very subtle adjustment at the top is all you need to do.

If your thinking this might be a machine you need to add to your workshop contact us. Once you have one you’ll wonder how you ever got by without it. Honestly it’s probably the most used piece of equipment we have, and not just for the crafting of knives, but indeed for many projects engineering and others. The variable speed for example makes it great for finishing up the edges of leather sheaths and the wooden handles without burning the material. With 38 years of experience in the engineering industry I’ve used a lot of linishers and belt grinders for sure, but when it comes to the 2 x 27 belt grinder, I just love it.

The Dirty Old DIY Forge

Not so old really if the truth be told, about twelve months in service at this point in time.

Eight soft fire bricks make up the main body, with two hard fire bricks in the front and back. The frame is stainless steel angle held over the bricks with threaded rod. It makes it easy to disassemble when the bricks need to be changed. And they will need to be changed at some point in time, I’m thinking maybe next time I might put a hard fire brick on the bottom, but that’s just an idea.

It’s got a Frosty Tee type burner on the top and a 30psi regulator at the bottle and it all runs like a dream, all be it a noisy dream, but that’s how it’s meant to be.

The only downside is that’s it’s quite small, a 12″ blade about the best it can handle, and a cleaver being quite a stretch, in my opinion anyway.

All this being said it’s perfect for what we need. In time we’ll probably update to a heat treating oven, but when you weigh up the costs or you’re a beginner knife maker looking to get into the craft, one of these is a good place to start.